How much does barrel length impact bullet velocity in .38 Spl and .357 Mag revolvers? We tested 8 different loads in 11 different guns to find out.

Watch the video below for a summary of the results, or keep reading for the old fashioned text version.

A lot of you guys have been asking about the status of our .38 Special and .357 Magnum ballistic gel tests. We are very close to having that wrapped up and I’ll be sure to let you know as soon as the results are ready.

In the meantime, I wanted to give you a quick look at some of the background research we did before we started the actual gelatin tests. With .38 Special, and especially with .357 magnum, conventional wisdom says that barrel length has a huge bearing on the effectiveness of the bullet. The longer the barrel, the greater the velocity, and for self-defense rounds, higher velocities often translate to better penetration and expansion. The same could be said for the semi-auto calibers that we’ve tested in the past, but .38 and .357 cover a much broader range of velocities than any one semi-auto caliber and that means barrel length tends to be an even more important factor with revolvers.

So for our ballistic gel tests, we wanted to test each load with both of the two most common barrel lengths for defensive revolvers, which are 2-inch and 4-inch. But deciding which guns to use for the tests was a little tricky because, for example, not all so-called 2-inch snub nose revolvers are actually 2 inches. Some are 1 ⅞ inches or 2 ⅛ inches or 2 ¼ inches, and we weren’t quite sure how much of a difference it would make in our test results if we chose one snub nose over another. We also wanted to verify that there was a significant difference in velocity between the two inch and four inch guns we were planning to use before we started shooting up our expensive gel blocks.

So we got out the chronograph and measured velocity for a few different loads that we just happened to have in the safe – four .38s and four .357s. We ended up testing these through a lot more guns than we originally planned. In total, we got velocities from 10 revolvers and just for fun, I also brought along the carbine.

We fired five rounds of each load through each gun and took the average velocity. Here’s what we came up with:

| Firearm | Ruger LCR | Kimber K6s | S&W 640 | Ruger SP101 | S&W 386 | S&W 66-6 | S&W 28-2 | S&W 686-3 | Ruger GP100 | Taurus Tracker | Marlin 1894 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Barrel Length | 1.875″ | 2″ | 2.125″ | 2.25″ | 2.5″ | 3.16″ | 4″ | 4″ | 4.2″ | 6″ | 17″ |

| load | avg | avg | avg | avg | avg | avg | avg | avg | avg | avg | avg |

| Federal .38 Spl 130gr FMJ | 762 | 793 | 764 | 807 | 832 | 844 | 763 | 828 | 852 | 885 | 1041 |

| Winchester .38 Spl 148gr Wadcutter | 698 | 713 | 701 | 722 | 709 | 741 | 746 | 740 | 764 | 763 | 896 |

| Federal .38 Spl 158 gr SWCHP +P | 754 | 788 | 804 | 820 | 797 | 872 | 917 | 882 | 892 | 921 | 1135 |

| Speer .38 Spl 135gr Gold Dot +P | 853 | 863 | 884 | 886 | 894 | 927 | 874 | 945 | 987 | 982 | 1084 |

| Magtech .357 Mag 158gr SJHP | 1008 | 1031 | 1063 | 1030 | 1043 | 1192 | 1190 | 1105 | 1210 | 1288 | 1711 |

| Winchester .357 Mag 110gr JHP | 1160 | 1188 | — | 1187 | 1183 | 1273 | 1234 | 1265 | 1330 | 1304 | 1725 |

| Hornady .357 Mag 135gr Critical Duty | 1116 | 1144 | — | 1181 | 1177 | 1242 | 1257 | — | 1272 | 1319 | 1459 |

| Remington .357 Mag 125gr Golden Saber | 1077 | 1100 | — | 1133 | 1125 | 1232 | 1277 | — | 1240 | 1294 | 1600 |

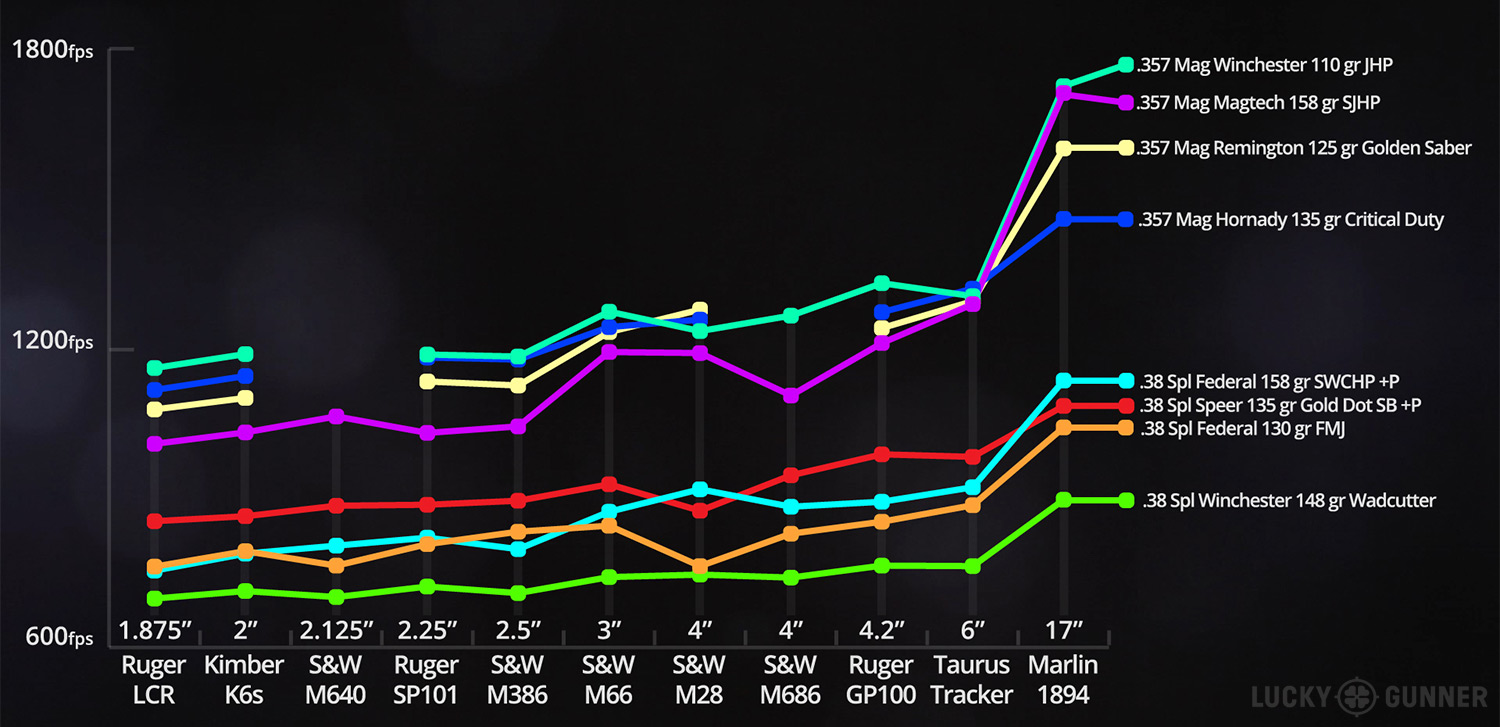

There is another piece of conventional wisdom that says every time you add an inch to the barrel length, you should get a velocity increase of about 50 feet per second. That might be a generally decent rule of thumb in some cases, but obviously it’s not absolutely true. That becomes easier to see when we view the same data plotted on this festively colored line graph:

We didn’t have the S&W 640 Pro or the S&W 686-3 available when we took all of the velocity measurements which is why there are some gaps in the data. Taking a quick glance at the chart, it’s readily apparent that the velocity generally increases with barrel length, but not in every case, and the rate of increase is not predictable. If we tried to predict this data using the “50 feet per second per inch” rule, each line on the graph would progressively rise higher as the barrel length increases from left to right. In some cases, however, the velocity actually drops going from a shorter to a longer barrel.

The most significant instance of this phenomenon was the Smith & Wesson Model 28-2, which took a huge nose dive in velocity with the two jacketed .38 Special bullets compared to the 3-inch barrel and the other two 4-inch barrels. The S&W 686-3 also showed a major drop in velocity with the Magtech 158 gr .357 Magnum load even though the same barrel had comparatively high velocities with some of the other loads.

There was also some up-and-down going on among the sub-3-inch barrels, but to a much lesser degree. For every load, there was a velocity increase between the 2-inch barrels and the 4-inch barrels, but adding an additional two inches did not always produce greater velocity from the 6-inch barrel.

Obviously, this is a very small sample size for both the ammo and the guns we tested, so take these results with a grain of salt, but there are a few things I think we can learn here. First, there are a lot of factors influencing velocity besides just barrel length. For example, the Model 28-2 we used was made in the 1970s and the 686-3 is from the 80s. All the other revolvers we tested are fairly new. It could be that those older revolvers were made to be optimized for loads we didn’t test. Maybe they have a different rifling twist rate, or a wider cylinder gap or maybe the chambers aren’t as tight. The 6-inch Taurus revolver has a ported barrel, which might account for it’s fairly unimpressive velocities. The bottom line is that when you’re looking at barrels that are very close in length, you can’t make any assumptions about velocity until you actually measure it.

I think it’s also safe to say that among modern snub nose barrels around two inches, there isn’t likely to be a huge difference in velocity. We chose to use the 2-inch Kimber K6s for the actual gelatin tests because it’s got a steel frame so firing the magnum loads is more tolerable than a lightweight gun. The Kimber also showed pretty middle-of-the-road velocities compared to other short barrels.

For the 4-inch test gun, we decided on the Ruger GP100. It is technically longer than 4 inches — 4.2 makes it legal to own in Canada — but it’s one of the most popular 4-inch revolvers on the market, and the velocities we measured with it didn’t show any unusual outliers.

If this kind of nerdy velocity stuff gets you excited, check out Ballistics by the Inch. Those guys have done basically the same thing we did here, but they’ve got results for just about every handgun caliber and barrel length you can think of. If you want to know whether any of this velocity stuff actually has a real impact on self-defense bullet effectiveness, be sure to check the blog again soon for our ballistics gelatin test results.

EDIT: A reader shared with us this article originally printed in the 1974 Speer Reloading Manual. It includes the results of Speer’s velocity testing of three different .357 magnum loads with 30 different firearms. The purpose of their test was to illustrate the same basic principle we discovered here: every gun is different and you don’t really know what velocity you’ll get until you measure it.

Excellent write up guys.

One point of contention in your tests, and I hope you haven’t already shot up those expensive gel blocks. The LSWCHP 158gr +P .38 special, the “FBI load”- I noticed you may be using the federal load in this report. My understanding is that the Remington brand load is(or perhaps, was, I’ll explain) the favored “big brand” name load for snubnose revolvers over federal, winchester, etc; because the slug deformed the most in tests from short barrel guns. Some say its because the Remington load uses a softer lead projectile.

Now, as for that, its my understanding that Remington has changed at least the packaging of their “FBI load”, from their “express” line, to the HTP, or “High Terminal Performance” line. Some folks have said that the load itself has also changed and is not producing the same performance…….

And, no-one that I have seen has tested the new HTP “FBI load” in gelatin to determine the status of it.

Many knowledgeable snubnose enthusiasts do consider the Remington LSWCHP 158gr +p “FBI load” to be the best of the big brand offerings, and would be very appreciative of a test to clear this up.

I know I would.

AND- Thank ya’ll very much for all your hard work!

Thanks for mentioning that. That is more or less what I learned after speaking with a couple of people about the various iterations of the FBI load. We tested both the Federal and Winchester versions, but the Remington FBI load with the HTP packaging has been difficult to find lately. We did finally get our hands on a box a few days ago. I can’t promise it will make it into the initial test results that we’re going to be releasing shortly, but if it doesn’t, we will definitely add it within a couple of weeks afterward.

Good enough for me my brother.

Again, thanks for all the effort, and of course the expense, in presenting these tests.

And when you do so don’t forget to include the Youngs Modulus for John Ayer……. 🙂

I think you are correct on the Taurus 6″ barrel. On the Trackers I have seen, the barrel really stops about an inch short of the muzzle and there is a large open area (I call it an expansion chamber, but that term may not be technically correct) where the porting is. So you are really testing a barrel closer to 5 inches. Between that and the fact that there is just inherent variation between guns, I’m not too surprised by how close the numbers on that gun are to the 4 or 4.2 inch barrels.

Also, it’s a Taurus…

That’s what I was trying not to say with “inherent variation”.

“Inherent variation?” Is that PC for “shouldn’t have bought it?”

I assure you, it lives in our safe for testing purposes only.

Don’t blame you. If it broke, your grandkids will be old before it got fixed right. I’m a Ruger GP100 fan. I can’t afford a S&W TRR8 because my wife carries, but at the moment that’s my dream-gun.

Yeah, it wasn’t made by shiny white Americans, so it doesn’t count as an actual gun.

Their not racist cgray. They are are just gun snobs who think only smith and ruger can build a revolver. Maybe with a Kimber thrown in there. Reminds me of the guy I used to shoot with. Only would shoot ak’s because he said they were so “reliable.” His jammed every fourth or fifth round. But he kept it because it was so much better than an ar. Smh

Excellent stuff. You should’ve also tested rounds specifically designed for snubbies like the the Gold Dot “Short Barrel” for the 38spl. and Hornady’s Critical Defense line.

Do they really work and expand on short barrels, and will additional barrel length add anything to their performance?

The Gold Dot load we used in the velocity test is the short barrel load. We tested other short barrel loads for our upcoming gelatin test.

Sweet. The gold dot short barrel is actually my load of choice, but I like to keep that rem FBI load around, too.

You guys just need to grab up a Wesson 15-2. Same frame, plus control over the cylinder gap.

Hey, y’all. Mind throwing a few 357 Mag HPR 158gr XTPs at your gel? I’d like to see what the advertised 865 ft-lbf translates to visually. I won’t insist on you needing to shoot it in the lighter guns, but a nice foot-long muzzle-flash is pretty too.

Hey Chris! Great writeup. Any chance you tested the classic fed/rem 125 357 SJHP? It would mean the world to me and likely a few others. Good data on speers 357 GDSB is also nearly impossible to find. Thanks again for all you do.

https://uploads.disquscdn.com/images/26fd21ca34a5218eb9c5dfe7233e7d9c46322d089171613edd9e26ab414c8449.jpg Hi Chris,

You’re one of the very few that reliably tests the venerable wheelgun and the torpedos we stuff into the tubes. I like the Remington 125gr Golden Saber +P in the Special. I think it’s one of those rounds that flies under the radar and is a good one. If memory serves, velocity is around 990-1,000 fps out of a 4-inch tube. The 4-inch .38 service revolver is what I mostly have around the house. That particular weapon system has made more evil men permanently good than anything else…

Can I trouble you to include the Golden Saber +P in your upcoming gel tests? I’d also like to see your thoughts on the Buffalo Bore full wadcutter loads in the Special. Does the sharp non-expanding shoulder work by cutting and penetrating through the target?

I enjoy your videos. They’re very well-done.

Both the .38 +P and .357 mag Golden Saber loads will be in our test results. We didn’t test the Buffalo Bore wadcutter, but we did try the Winchester wadcutter. Clear Ballistics gel is a questionable medium for examining wound channel characteristics other than penetration depth, so I can’t comment on the cutting effect in our tests. But as I mentioned in my wadcutter article, reputable authorities in the wound ballistics field seem to agree that the sharp shoulder does create a far more effective wound channel than round nose or non-expanding HP bullets. The Winchester load we tested penetrated well, and I don’t know that you’d be gaining much by pushing the wadcutter another 100-200 fps, especially considering the benefit of extremely low recoil from the lower velocity load.

Hmmm, “far more effective wound channel”.

I guess that would depend on the specific goals of shooting. There is a book you may want to study, “Gunshot Wounds: Practical Aspects of Firearms, Ballistics and Forensics” by Vincent J.M. Di Maio.

“Effective wound channel” normally gives the reader a pretty good indication of the author’s ‘specific goal of shooting’. One normally doesn’t use that term when describing target ammo.

When I’m considering personal defense ammo, I most certainly want the one that creates a “far more effective wound channel” when compared to another load. Doesn’t everyone???

Define “effective” in the context of wound channel. One of the reasons the wound channel of the 5.56 NATO is considered to be more effective than other bullets, the 7.62 NATO for example, is the way the bullet yaw effects the wound channel and bullet break up.

Read the book I suggested, pay particular attention to chapters 3-6.

One suggestion: take Ruger GP 100’s in, say, 2.25, 3, 4.25, 5 and 6″ guns and run those numbers. Then take Ruger SP101’s in various lengths and do same. Then take S&W and do same. This will negate things such as gun age, different tolerances from different makers and models of guns while still allowing a comparison within, say, GP100 revolvers.

I nerded out for hours when I first discovered Ballistics by the Inch. Im glad they got a mention here.

You folks just keep coming through with these great studies with relevant data! This is good stuff! This is what keeps me coming back to your site. Well, that and your ammo prices…

With smaller calibers and fast burning powder, barrel length is not a big issue and you can have too much barrel. But in larger caliber revolvers like the .44 magnum, barrel length does matter.

This study does not have enough data to even begin to make these claims. What is the headspace of each of these revolvers?

I would bet that velocity drops are related to either headspace or groove/land diameters or both.

What is the average bullet diameter in millionths? You’d be surprised how much velocity loss is created by a 50 millionths variation in bullet diameter or barrel diameter. With so few bullets each should be measured in a shadowgraph. Then it depends on material, lead compresses more easily than copper so thickness of the copper jacket can important.

You could use more data, 30-50 of each firearm version and each of those 330-550 firearms shooting 30-50 of each variation of ammo, so, around 80,000 rounds of ammo minimum, 220,000 rounds would be better.

Too many unrecorded, unknown, variables and too little data. Add headspace and barrel diameter in millionths and that would help, but, not much.

This study has more information than many, MANY studies available on the net. Most of us are not interested in miniscule differences created by ‘millionths’ of an inch in bullet diameter, the nearly imperceptible compression differences between copper and lead, or the fixed dimensions of headspace and L&Gs (which are available from the mfgr.).

Why not read it and appreciate the work that LG put into it rather than picking on essentially inconsequential details or tolerances that the average handloader is not concerned about due to their extremely limited impact on the results? In your last sentence you, yourself even admit that the info you are calling for is not that essential.

Honestly, some people are not happy unless they are complaining about something, ANYTHING!

There isn’t even enough data to claim that the average velocity of a tested ammo when fired through a tested revolver is X.

We don’t know the ranges or standard deviation of velocity. It looks to me like the numbers are close enough that there is overlap.

This test doesn’t give me any reliable information regarding the velocity I can expect when a specific round is fired through a specific gun and the authors admit as much when they conclude that “every gun is different and you don’t really know what velocity you’ll get until you measure it.”

Which is and isn’t true. Without data I won’t know, but, if I do enough testing and identify the variables correctly I can give you an accurate expectation of velocity based on those variables.

The Young’s modulus of copper is 17. Lead is 2. Hardly imperceptible.

If you’re not happy with the results of the data, then dismiss it and move on. Or better yet, do your own study and post the data.

No one here wants to listen to your rants about variables that could have been considered, but weren’t. I don’t recall reading anywhere in the study that this was an absolutely all-inclusive, absolutely bullet-proof study. In fact the author even stated that it wasn’t.

Young’s modulus, when applied to ballistics, is pretty much limited to impact deformation of projectiles, not to the imperceptible deformations taking place in a firing chamber. We’re talking about pistol cartridges here, not 2500 yd precision rifle shooting.

If you want to whine and nit-pick, go somewhere else.

Young’s modulus has nothing to do with ballistics. Young’s modulus has to do with the tensile strength and compressibility of materials, which does influence impact compressibility, and projectile resistance when being swagged through a rifled cylinder. A variation of 50 millionths of barrel diameter can increase resistance to motion over 1000 newtons. That can do two things, it can increase pressure and resulting bullet velocity and, in the case of a revolver, allow more gas to escape through the headspace.

So, yeah, pretty important to understanding projectile velocity..

We aren’t discussing terminal ballistics here so your comments on impact deformation have nothing to do with velocity.

There isn’t any real data in this study. Look at the velocity overlap in the study I linked to, which is not a velocity study. I’m not writing an essay on all the statistical errors in this study or your ridiculous attempts at generating conflict so you can win a prize to become a legend in your own mind. This is a discussion and you don’t win anything. You either learn or you don’t. Your choice. I’ve just pointed out what is needed statistically to have an end result less ambiguous than “every gun is different and you don’t know what you get”.

You either document more variables or you shoot more guns/ammo. Being a shooter and a manufacturing engineer with over 10 years in research and development I like the shooting option, but, I could do either.

If you don’t like science don’t try pretending you know anything about it because I doubt if you could design a research project to save your life.

Try defining the study research question. Define the hypothesis being tested. Tell me, was the hypothesis proved or disproved?

Hypothesis: in general longer barrels result in higher velocity

Result: proven in general

It appears you are the one who wishes to become a ‘legend in your own mind’. I worked in the engineering and scientific fields my entire career. That is, before I retired comfortably at 54. And I, too, have been a shooter for quite some time. Apparently much longer than you.

You seem to have some hang-up on Young’s modulus which is essentially INCONSEQUENTIAL. And yes, in this application, it most certainly does have something to do with ballistics. You can’t even see when you’re contradicting yourself! The range of YM spans from microscopic to nearly 5000, depending upon the material, so your claim of a difference between the YM for copper being 17 and lead being 2 is INCONSEQUENTIAL for the everyday shooter.

Why do you insist on coming on here, with a total of 8 comments on Disqus, total, and trash a study that was done with nothing but good intentions and DOES provide a lot of useful information for the everyday shooter?

Go shoot your arrogant, self-important mouth off somewhere else. These people at LG do a good job on these studies AND they explain the limitations and parameters of the study in the text. They never claimed their studies were all-inclusive and all-encompassing.

If you want to read a study with more information than the average shooter wants or needs, I suggest you go to NIST or SAAMI. They have lots of studies there and I’m sure you can find lots of other self-important idiots like yourself that you can argue with about how YOU would have conducted this study or that experiment, since YOU have it all figured out with all of your extensive experience. As I said before, no one here wants to read your whines and complaints.

WE are thankful to LG for providing this information. Unlike you, who chooses to do nothing but complain about what it doesn’t have.

Doubtful, very doubtful. I actually retired at 49, not quite 50.

You managed to write a lot of insults and not answer any of the questions I asked.

So, I assume I’m correct in my assumptions regarding your skills, especially since you are wrong about the compressive issues regarding YM.

Oh whatever John! Whatever you say is correct. Is that what you want to hear? You are so full of yourself I’m surprised you have room for your guns. And your claim of retiring after a long 10 year career is extremely doubtful. I think it’s entirely possible your career ended at age 49 but I seriously doubt it was by voluntary retirement. No one wants to work with, or even employ someone who is so argumentative that they have to argue about something even when the other person tells them they’re essentially correct. Despite the fact that it’s impact is so small that it’s inconsequential.

I actually did retire at 54 after a long and fulfilling career of developing and coordinating numerous Superfund projects, all but one of which came in ahead of schedule. I dealt with argumentative AHs my entire career considering I had EPA officials in my office pretty much everyday so you’re nothing new. I’m 58 now and enjoying life immensely.

How’s life in your land of negativity? Has anyone else in your life ever been correct about anything?

I’m not arguing, you are. I pointed out ways that the study could be made better and you went off on a troll rant. I’m just sitting back listening.

Guys like you didn’t want to work with me because I’m the guy they call in to fix things guys like you did wrong.

Technically it’s called meta cognition. In practice, it is failure based on bad assumptions. For example, your assumption that the difference in resistive friction in the barrel between compressing a copper jacketed bullet and a lead bullet is inconsequential.

I’m the guy who comes in, looks at the assumptions which are causing failure and addresses them.

In this case, I can almost guarantee that barrel diameters, forcing cone alignment with barrel, chamber size, ammunition and headspace being equal a revolver with a longer barrel, up to about ten to twelve inches (depending on powder burning speed) will produce a higher mean projectile velocity.

Where the conclusion of this study is, “you don’t know till you test it”.

But, keep ranting. It alleviates my boredom and reminds me of all the times managers of guys like you apologized to me. I only cared that the check cleared.

And only the last ten years was R&D. That was the most fun.

Production problems are easy because the last few thousand people probably did it right. R&D is different because people try and apply what they “know” to something they know nothing about.

I just need to know the difference between what I know and what I believe where others think they are the same thing.

And I’ll give you a clue to solving almost every problem ever. Once you know what you know, what you believe and the difference between the two, look for the area of most variability. Once the bad assumptions are eliminated, that’s where the problem is.

Yeah, yeah. Keep denying to yourself. That will make you more likeable.

Actually I wasn’t the one who made the errors in the projects that I ran. It was usually the mechanical engineers who are the ones with the big egos and are never wrong. I’m assuming that’s what you are. And no, I wouldn’t want to work with you. You have to be right at all costs.

But, even despite the mistakes made in design by the MEs, I was able to bring my projects in ahead of schedule. I can’t say they were under budget because anytime EPA sticks their noses in, the costs go up.

You still don’t see what I’m trying to get across to you do you?

Nope wrong again, I’ve just studied mechanics like I’ve studied other things. You just can’t stop making bad assumptions.

And you are exactly who I thought you were, someone who blames others when things you are responsible for go wrong, which is exactly the kind of people I had to clean up after.

Yeah, you like participation awards, “we did a great job even if we didn’t prove anything and we spent a lot of money not doing it!”

Which is why you hate guys like me that figure out how to get the job done.

Dudes, give it a rest. We already know engineers don’t have people skills, you don’t have to keep trying to prove it.

Depends on the people Chris.

You’re not people. You are a differential equation walking the earth in continued agony because it is not as precise as you want it to be. You must be disappointed with so many things in life….LOL

Sorry LG Chris. Keep up the good work. Almost all of us appreciate what you’re doing.

The author proved a general trend and you just cannot accept this. Let me guess, you voted for the Hildabeast and just cannot get over the election results? Right?? And I’ll bet you re-live election night each waking day, hoping for a different outcome than what actually happened. I hit close to home did I?

John, seek help for this YM fixation now before it consumes you. YM is the slope of the graph of a material while it is in the linear elastic range and has virtually nothing to do with studies like this that are important to the big picture. The “big picture take-away” here John, is that in general and up to a certain point, longer generally results in increased velocity. There are some outliers but in general the longer barrel (up to a point) gives greater velocity. Of FAR, FAR,FAR more importance than say 825 fps from a 2.25″ vs 865 fps from a 4″ for .38 special rounds is how it recoils, how much it weighs, how it looks and may carry, etc. 10% more velocity is absolutely meaningless if it doesn’t feel or look good or if it recoils too much. So….. GET OVER SPECIFICATIONS ON VELOCITY AND MUZZLE ENERGY FOR SMALL REVOLVERS. ASTHETICS, FEEL, WEIGHT AND RECOIL ARE MORE IMPORTANT….BY A LONG SHOT (no pun intended).

I am an engineer and can tell you that what you are asking a study to do is meaningless as you could never find ammo to match that which was used in said study because ammo is not sold based on such criteria you want to see in your “perfect study”. If you over analyze things in life you will have a miserable life.

By the way YM is the slope of the stress strain curve while in the linear elastic range and has virtually zip to do with this study. Now go away.

It does give a general trend and, even if you measured everything exactly it would be meaningless to the average shooter since there is no way to get or replicate those exact dimensions when you go to buy ammo the next time around. The “general” take away is that going (for example) from a 2.25″ to 4.25″ gets you a bit more velocity, maybe on the order 4-11% for .38 special and ballpark 9-17% for 357 magnum rounds. “In general” longer “tends” to be more velocity. For those agonizing over choosing a 2″ vs 4″ the velocity difference is relatively meaningless so get the one you want base on other factors that are really more important (which this study does not show) such as recoil, how it feels in your hand, weight of gun, ability to better hit your target with a longer barrel, etc. so….for all you weenies who want to micro manage bullet diameter, twist, headspace, etc, PLEASE, PLEASE seek help to get over this need to over-spec everything.

But there is enough data to show that when the same ammo is used in barrels of different lengths that a general pattern begins to emerge. And that’s a fact you refuse to accept. Seek help from those more technically competent than yourself.

Abraham Lincoln said people are about as happy as they want to be. I guess some people just don’t want to be happy about anything.

While those variables do exist it does show a general trend and that’s all that’s important.

You’re the same kind of person who needs more data to tell you why T r um p beat the Hild a be ast……LOL

Could it be the Cylinder Gap? Theory – If the cylinder gap is loose it would bleed out pressure more. The older models could be worn and have a bigger gap. With a bigger gap it would let the pressure fall faster and you would get less velocity at the end of the barrel.

Anyways, just a thought.

PS It was nice to meet you Chris at Tac-Con

And the author noted the two guns that were older, one a 1970 vintage, the other 1980 vintage.

What’s the fastest .357 Magnum grain load for Chiappa Rhino with 2 inch barrel? From your chart it looks like it might suggest 110 grain rather than 125 grain as I’ve seen on other charts. Thank you!

When are you going to do one on .44 Magnum/.44 Special? Or did I miss it?

lol those aren’t 357. If you aren’t breaking 1400fps in a 4″, then you are using sissy stuff.

These guys keep using full load 9mm out of a 4″ barrel and comparing it to weak 357 mag out of a 2″ and telling us that 357 shows no meaningful difference.

Interesting and informative…would have liked to see some 180 or 200 hard cast tested.

I’m more concerned with shot placement since our group shoots poker chips off fence posts the size of the gun makes little difference.

A shot in the eye ends the conversation in my opinion.

Every caliber known to man has probably been used at our lease and a question arose.

This question seems to not have an answer easily found online.

How does the 9mm generate upwards of 39,000 PSI and the 38 Spec only 18,000.

Both rounds are similar in dia and projectile weight you can choose from, yet the 38 seems to have the advantage on capacity for a powder load.

Both being 6 inch barrel wheels.

I just don’t understand the ‘twice’ the PSI that I am told I get with my 9mm over my 38 spec.

If a 9mm were shot out of a 38 spec wheel would the pressure go up only due to it being a 9mm round?

Thank you for the great information Chris. I’m going to buy the Ruger and can’t decide to go with the 4″ or 6″ barrel. I own two Taurus model 605’s in 357 which I use for concealed carry and both have been great gun’s which are carried under harsh condition’s at work also. I also own several S&W semi auto 9mm’s. I’m purchasing the Ruger as a carry gun when woods walking and for security carry and plan on purchasing a shoulder rig. Thank you again for the input and best wishes for you always.

yet the guys at the gun shop will continue to say ‘you’re not getting anything more than recoil and muzzle blast shooting a 357 out of a snubnose’

Yeah, you’re getting more recoil and muzzle blast, but also over 250 more fps, or 31% more velocity and 71% more energy, for the same weight bullet.

It’s pretty simple really, if the same gun kicks harder, then the bullet is coming out of the barrel harder. Equal and opposite reaction, physics 101. But many gun shop guys, are prone to reciting old wives-tales for some odd reason.

I carry a Taurus 605b2 loaded with barnes 125 grain tac xp hollow points 1200-1300 fps out of a 2 inch barrel is perfect for me?

Judging from the results of the LG testing on that round, it looks like a winner. Awesome expansion, penetration, and impressive velocity from a 2″.